Screws: Why it’s important to choose the right type for your project

Do you know how to select the correct screw for your home projects? The wrong choice could cost you time and money. This post will take you through the most common types of household screws and how to pick the right one for your project.

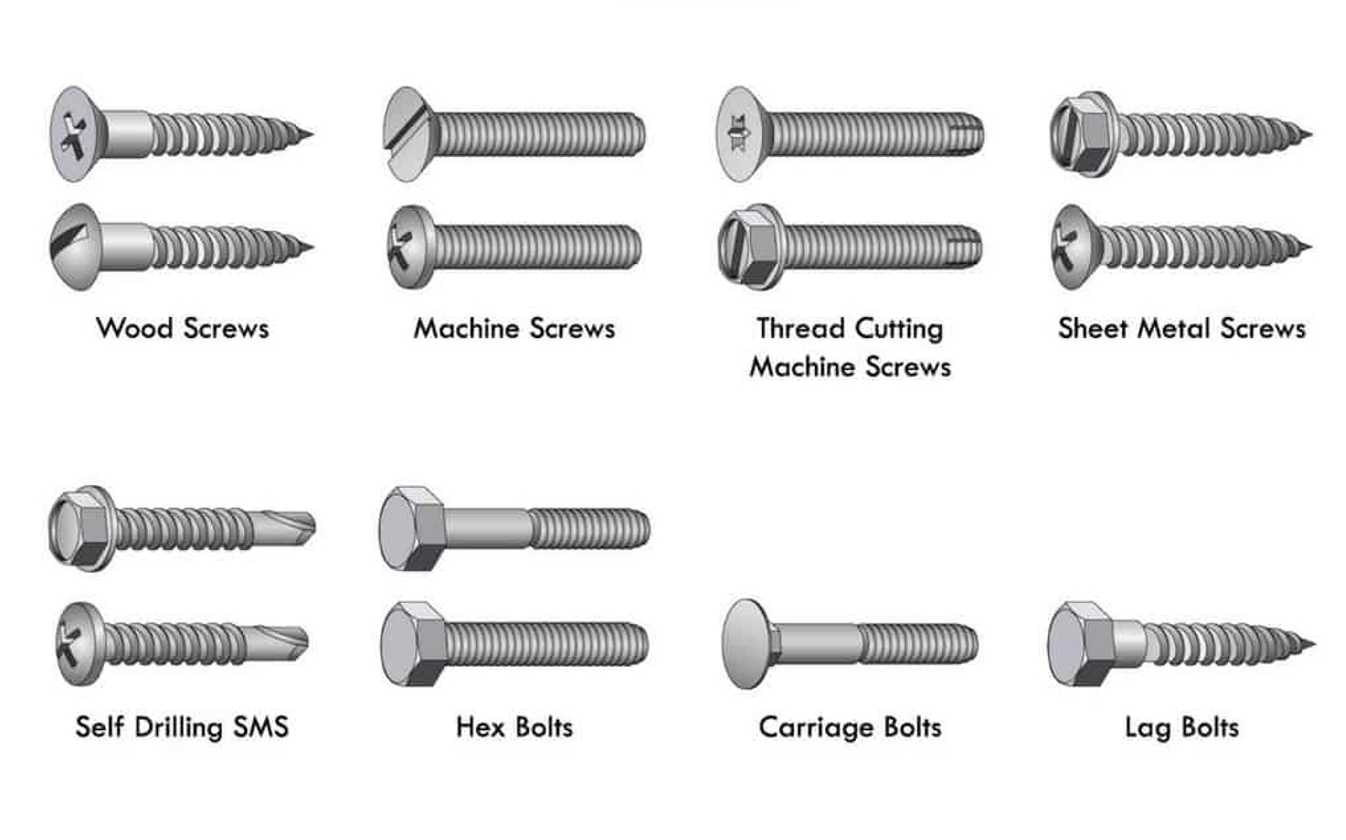

Material

The first thing you’ll notice if you visit your local hardware store is screws are categorized by the material on which they will be used- metal screws, wood screws, drywall screws, etc. Since screws are designed to serve specific applications you’ll want to have a clear idea of the project you are tackling and what materials are involved.

You’ll also notice screws are made of different metals. Some of the most common are steel (most widely used), aluminum, copper, and titanium. These metals have several properties related to hardness, strength, weight, and finish. See the chart below to learn more.

Image Source: www.nationalbolt.com

It will be important to have an awareness of the benefits of the various metals and to help determine the type of screw you need. Making the right selection will also depend on the environment the screw will be used in.

Screw Head Types & Uses

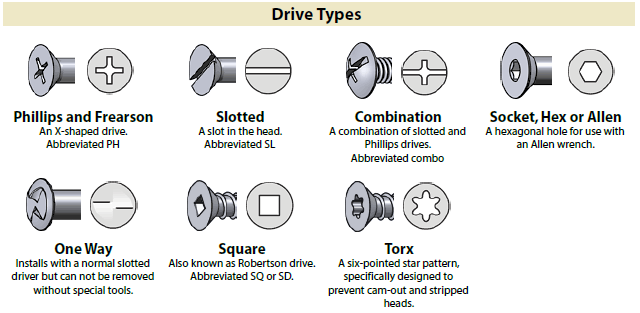

The most common two head types of screws you’ve likely heard of are slotted and Phillips. For a period of time Phillips was the most popular choice. However, over the past few decades with the increased use of power drills/drivers, new head types have been developed that better prevent stripping and slipping. Some designs have specific capabilities including tamper prevention, stability during installation, reliability in application and strength for high-torque insertion. Let’s dive in and take a look at the features and benefits of the various options.

Slotted

Slotted screws have a straight line through the middle of the head. They are used for simple joints or projects that use hand-driven tools and require little torque, such as attaching a faceplate to an electrical outlet.

Phillips

The Phillips screw is more commonly used than a slotted screw because it’s a lot more stable with four contact points on its head. The self-centering bit makes it faster to locate than a single slot. Beyond that, the design also reduces slippage. Phillips heads are typically used on appliances, machines, hinges, and other hardware.

Multi-Head

These types of screws are typically used in building and machine industries because they more effectively use the torque delivered by a power drill or pneumatic tool. They are also less common and are therefore used on some consumer products to discourage people from disassembling them. Here are some of the most common multi-head screws used for construction and household purpose…

Torx (star shape)

Due to its uncommon driver type, early use of the Torx screw was for security, (think schools, correctional facilities, and public buildings), where the ability to remove harware needs to be discouraged. However, as the drive has gained popularity, other drives have been invented to fill this role.

Today, Torx screws are commonly use on automobiles, motorcycles, bicycle brake systems (disc brakes), hard disk drives, computer systems, consumer electronics, and are also becoming increasingly popular in construction industries, as well. Builders are using them for structural framing, finish work and even as wood-to-concrete fasteners.

By design, Torx head screws resist cam-out better than Phillips head or slot head screws. They are a great option when many screws are needed since they grip the driver well and provide minimum wear to drill bits.

Hex screw (six-sided)

In order to use Internal Hex screws, you’ll need an Allen wrench to install or remove them. If you have ever purchased pieces of furniture that you have to completely assemble (ahem… IKEA perhaps), or at least partially assemble, you’ve likely come across or needed this type of screw.

Quadrex

The Quadrex is a combination of square (Robertson) and Phillips head screws. They are relatively rare, though they provide a great deal of stability, allowing those using them to work quickly. This design allows for lots of torque to be applied, which makes it a great option for driving-intense options like framing or building a deck.

Head Shape

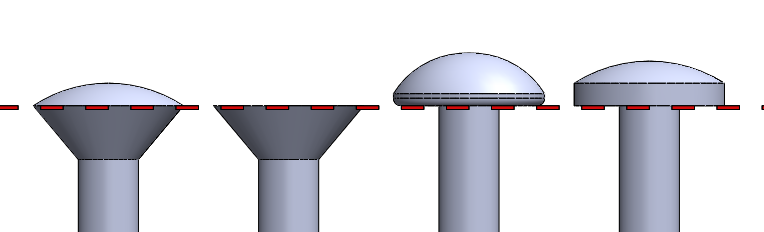

Some head shapes are designed to fit countersunk holes (flat-head and bugle-head screws), and others like the oval-head screw have a portion of the head that remains above the surface for decorative purposes.

Non-countersunk screws, such as those with round heads or pan heads, rest on top of the surface.

Diagram shows an oval countersunk head, a flat countersunk head, a round head and a pan head both of which are non countersunk. The red line indicates where the screw will rest on a surface when installed.

Image Source: www.jayconsystems.com

Countersunk vs. Non Countersunk

You’ll want to decide on whether to use a countersunk or non countersunk screw. If you do not want the screw head to be visible on the surface of your material, picking a countersunk screw is the way to go. You’ll also want to invest in a countersinking drill bit and pre-drill the hole. We think predrilling is a good idea because you are less likely to split the wood, the project will look cleaner overall, and you can fill the holes with a wooden plug to give a nice finished look.

Not only is the look or aesthetic important when choosing a head type, safety is also something to take into consideration. For example, if building furniture you’ll want to avoid having any screw heads protruding on the surface to avoid injury. Countersunk screws are definitely the better choice for baby cribs, conference tables, office chairs, etc.

Whether you choose countersunk or non countersunk it is a good habit to predrill a pilot hole, especially when working with hardwoods. The size of the pilot hole will be the size of the minor diameter (inside threads) of the screw. This can take a lot of frustration out of a project and prevent splitting, cracking, and weakening over time.

Sizes

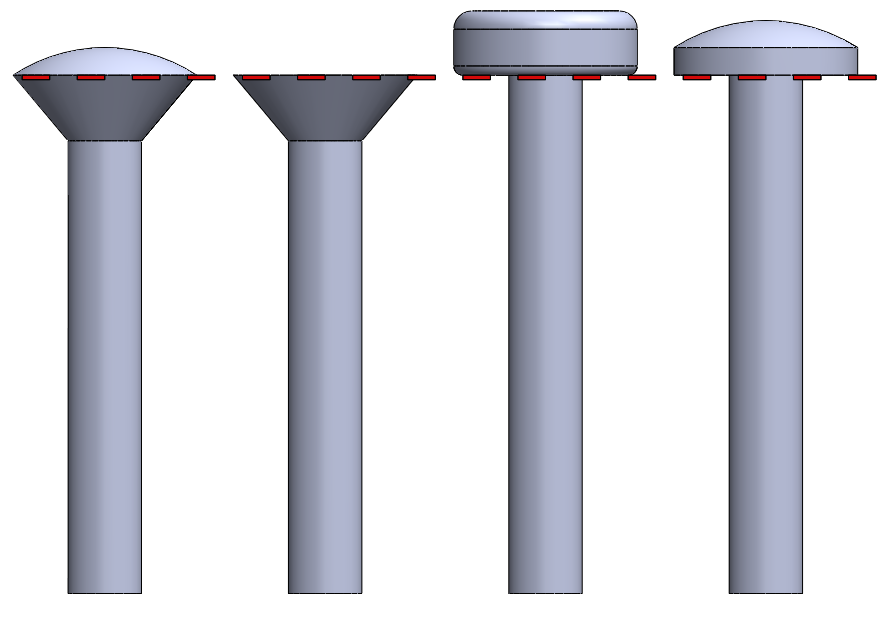

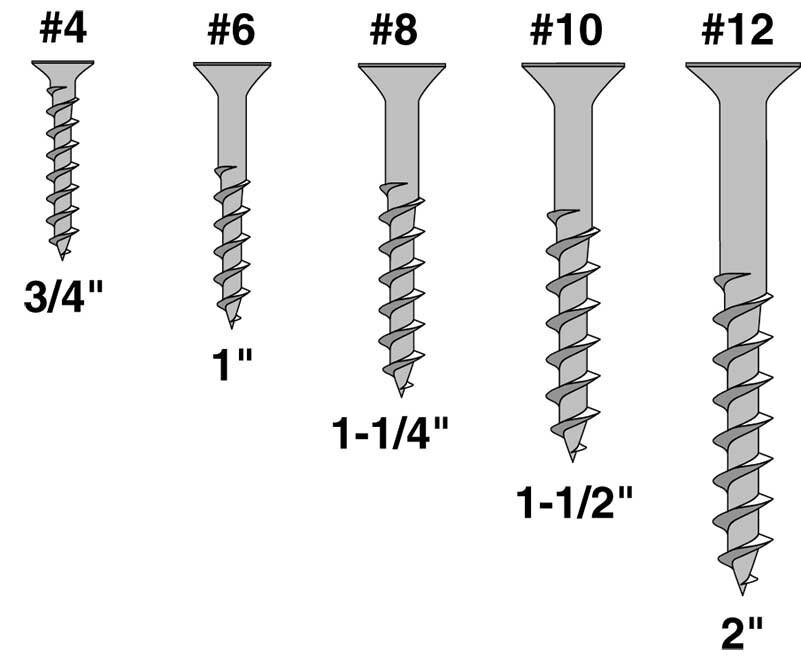

There are two measurements to consider when selecting the correct size screw; length and diameter.

Length

Length may seem self explanatory, but can be tricky since it is not simply referring to the length from one end to the other. The length actually encompasses the distance from the end opposite the screw head to the area where the screw would rest on a surface.

To further grasp this concept let’s look at the image below. The red dotted line is the starting measure point for these varying screw heads. Believe it or not all these are the same length, according to screw value measurement standards. Looking at the two countersunk screws on the left, some or all of the head is included in the measurement, but the other two on the right do not include the head at all.

When clearance is an issue, you can see how planning ahead and choosing the right screw is important. You’ll want to make sure you take into account where the head will rest on the surface to avoid any conflicts in safety or functionality.

The dashed line indicates the starting measure point for a screw. All the screws shown here have the same length.

Image Source: www.jayconsystems.com

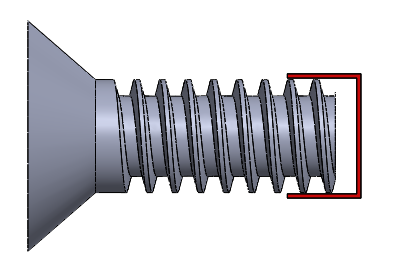

Diameter

To measure the diameter you would measure from the outer thread on one side to the outer thread on the other. This is called the major diameter and it is represented in the imperial system with a nominal measurement of #0 up to #14. The higher the number the larger the screw.

The major diameter is the widest part of the thread. It’s included as the diameter value in a screw’s value set.

Image Source: www.jayconsystems.com

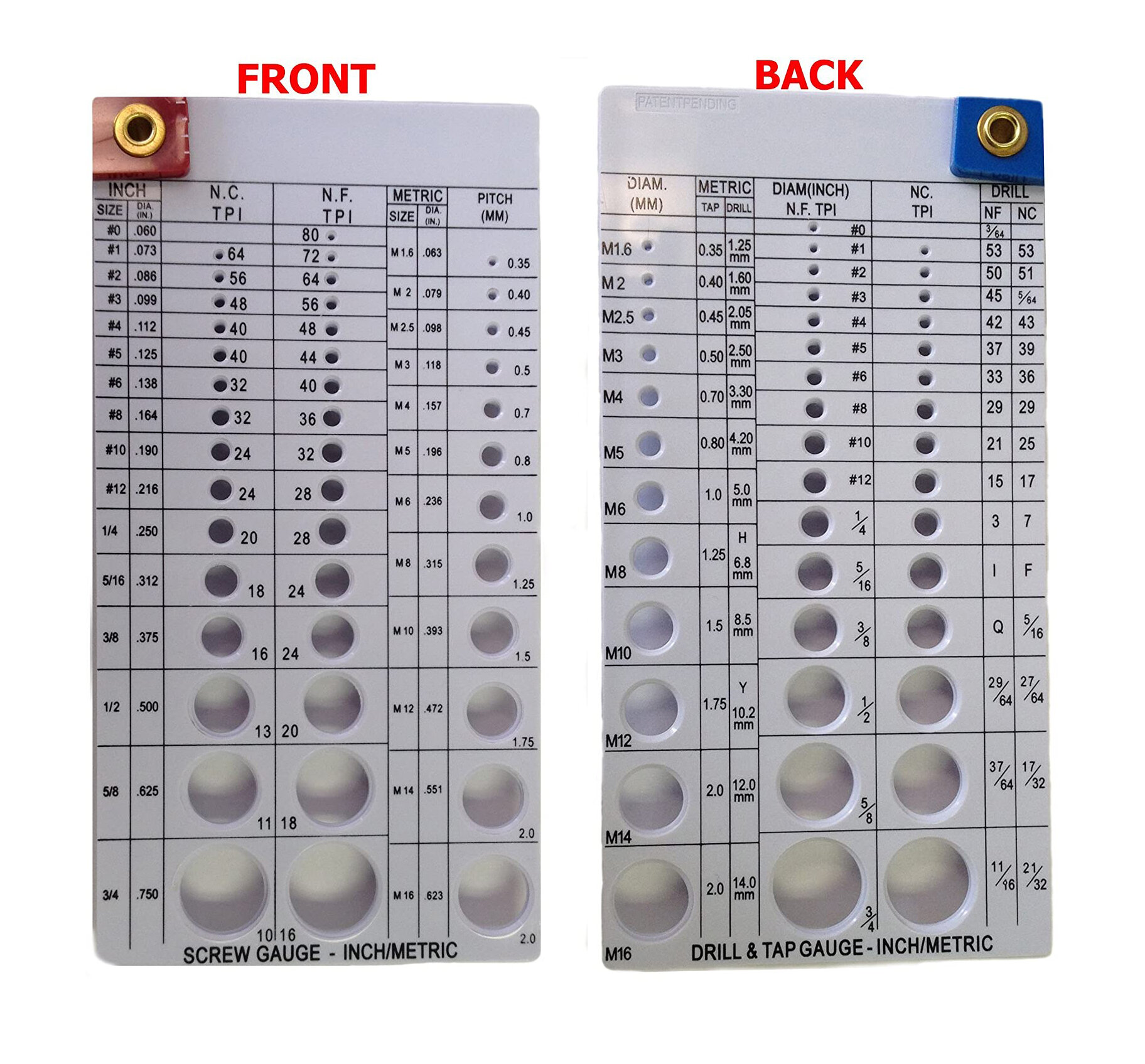

Luckily, if you are needing to match a screw or need to determine the length, gauge, or tread your local hardware store will likely have a handy board such as the one pictured below that can be a great resource.

If you’d like to purchase, you can find it here on Amazon.

Most Common Screw Types

The most common household screws you will likely use or run into while maintaining your home are wood, cement board, drywall, deck, lag, structural wood, machine, sheet metal, concrete, and multi-material screws.

It is important to keep in mind the three fundamental qualities of a screw; its gauge, its length, and the material on which it can be used, and you’ll be on track to choose the right screws each time! Hopefully, you’ve learned a thing or two and have extra confidence to pick the right fastener going into your next home improvement project!